AFT Bautzen converts the push plate assembly line in the Gläserne Manufaktur Dresden

The production of the new e-Golf is in full swing. It was recently converted to multi-shift production due to high demand. One more reason to modernize the production lines and adapt them to the new requirements.

AFT from Bautzen in Saxony received the order for the conversion.

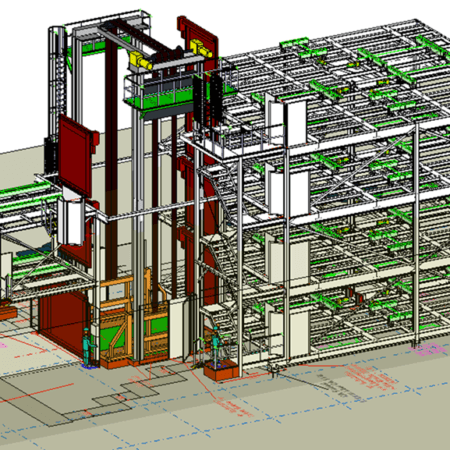

The conveyor systems of the oval-shaped production lines in the upper part of the factory, hidden under a wooden parquet cover on which the luxury limousine Phaeton was once mounted, are now being rebuilt by AFT Bautzen.

AFT can fall back on the experience of the previous conversion, which AFT and other Saxon partner enterprises of AFT accomplished with bravado and to the fullest customer satisfaction.

In this conversion, the innovative rail system under the assembly line and the associated new roller concept are used again. The special feature of this conversion is the extremely short period for all working steps, because there are only the three weeks of summer holiday of Gläserne Manufaktur available, then the e-Golf production will start again.